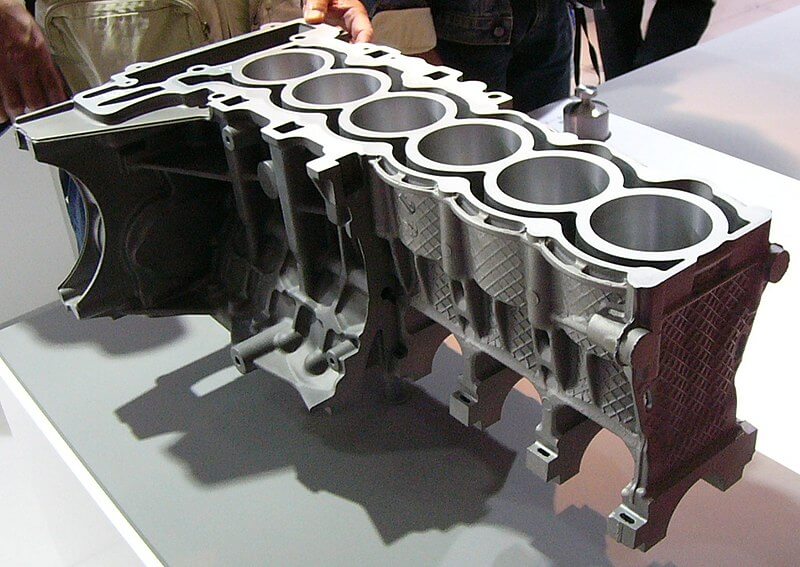

Die casting china is a manufacturing process that involves forcing molten metal into a mold cavity under high pressure. This technique is renowned for its ability to produce complex shapes with high precision and smooth surfaces. China, with its burgeoning industrial sector, has become a global hub for die casting, attracting businesses and investors from around the world. This article delves into the die casting industry in die casting china, exploring its growth, advantages, challenges, and future prospects.

Growth and Development of Die Casting in China

Die casting china industry has seen substantial growth over the past few decades. The country’s rapid industrialization and economic development have been pivotal in this expansion. With a large pool of skilled labor, advanced technology, and supportive government policies, China has emerged as a leading player in the global die casting market.

In the early 2000s, die casting china industry was primarily focused on domestic needs. However, as the country’s manufacturing capabilities advanced, Chinese die casting companies began to cater to international markets. Today, China is a significant exporter of die-cast products, serving various industries such as automotive, aerospace, electronics, and consumer goods.

Advantages of Die Casting in China

- Cost-Effectiveness: One of the primary reasons for the rise of die casting in China is cost efficiency. The availability of affordable raw materials, lower labor costs, and advanced manufacturing technologies contribute to reduced production expenses. This cost-effectiveness makes die casting china an attractive destination for companies seeking to optimize their manufacturing budgets.

- High-Quality Standards: Chinese die casting manufacturers have increasingly adopted international quality standards. Many companies are now ISO-certified and employ advanced quality control processes to ensure that their products meet global standards. This focus on quality has helped improve the reputation of Chinese die casting in the international market.

- Technological Advancements: China’s investment in technology and innovation has significantly boosted its die casting capabilities. The adoption of state-of-the-art die casting machines, automation, and advanced materials has enabled Chinese manufacturers to produce high-precision and complex components. This technological prowess allows them to cater to a diverse range of industries and applications.

- Large Production Capacity: China’s extensive industrial infrastructure supports large-scale die casting operations. The country’s ability to scale production according to demand makes it a reliable partner for businesses requiring high-volume manufacturing. This scalability is particularly beneficial for industries with fluctuating demands.

Challenges Facing the Die Casting Industry in China

Despite its growth, the die casting industry in China faces several challenges:

- Environmental Concerns: The die casting process involves the use of various chemicals and materials that can impact the environment. China’s industrial sector has been criticized for its environmental practices, and the die casting industry is no exception. The government is implementing stricter environmental regulations, which may affect production costs and operational practices.

- Intense Competition: The die casting industry in China is highly competitive, with numerous players vying for market share. This intense competition can lead to price wars and pressure on profit margins. Companies must continuously innovate and improve their processes to maintain a competitive edge.

- Quality Control Issues: While many Chinese die casting manufacturers adhere to international quality standards, inconsistency remains a concern. Variations in quality control practices can lead to defects and reliability issues. Companies must ensure rigorous quality checks to mitigate these risks.

- Supply Chain Disruptions: Global events, such as the COVID-19 pandemic, have highlighted vulnerabilities in supply chains. Disruptions in raw material supply and logistics can impact production schedules and lead to delays. Companies need to develop robust supply chain strategies to address these challenges.

Future Prospects

The future of die casting in die casting china appears promising, with several trends likely to shape the industry:

- Innovation and Automation: Continued investment in innovation and automation will enhance the efficiency and precision of die casting processes. The integration of advanced technologies, such as artificial intelligence and robotics, will drive further growth and improvement.

- Sustainability: There is a growing emphasis on sustainability in manufacturing. The die casting industry in die casting china is expected to adopt more environmentally friendly practices and materials. Companies that prioritize sustainability will likely gain a competitive advantage.

- Expansion into New Markets: As Chinese die casting companies continue to enhance their capabilities, they are likely to expand into new markets and applications. The demand for high-precision components in emerging industries, such as electric vehicles and renewable energy, will present new opportunities.

- Collaboration and Partnerships: Strategic collaborations and partnerships with international companies will enable Chinese die casting manufacturers to access new technologies, markets, and resources. These alliances will facilitate knowledge exchange and drive industry advancements.

Conclusion

Die casting china has evolved into a significant global industry, characterized by its cost-effectiveness, high-quality standards, and technological advancements. Despite facing challenges such as environmental concerns and intense competition, the industry is well-positioned for future growth. With ongoing innovation and a focus on sustainability, die casting china is set to continue its leadership in the die casting sector, offering valuable opportunities for businesses worldwide.